|

HeBei TuoHua Metal Products Co., Ltd.

|

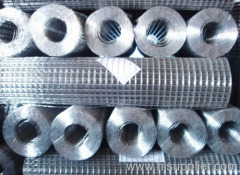

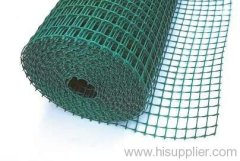

Welded Gabion Mesh

| Price: | 1.0~40.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

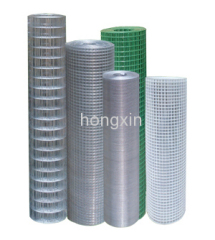

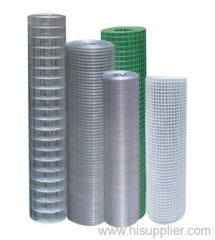

Welded Gabion are made from rigid, lightweight, galvanized steel mesh that allows for machine filling, holds the alignment of the face.

Welded Gabions

Description:

Welded Gabion are made from rigid, lightweight, galvanized steel mesh that allows for machine filling, holds the alignment of the face. Welded mesh gabions are faster to erect and do not need tensioning. This allows them to keep their shape, to be free from bulges and depressions and fit easily against the wall.

1.Material:Low Carbon Steel Wire

2.Feature:

1).Control and guide of water or flood

2).Flood bank or guiding bank

3).Preventing of rock breaking

4).Water and soil protection

5).Bridge protection

6).Strengthening structure of soil

7).Protection engineering of seaside area.

Applications:

1.Control and guide of water or flood

2.Flood bank or guiding bank

3.Preventing of rock breaking

4.Water and soil protection

5.Bridge protection

6.Strengthening structure of soil

7.Protection engineering of seaside area

Description:

Welded Gabion are made from rigid, lightweight, galvanized steel mesh that allows for machine filling, holds the alignment of the face. Welded mesh gabions are faster to erect and do not need tensioning. This allows them to keep their shape, to be free from bulges and depressions and fit easily against the wall.

1.Material:Low Carbon Steel Wire

2.Feature:

1).Control and guide of water or flood

2).Flood bank or guiding bank

3).Preventing of rock breaking

4).Water and soil protection

5).Bridge protection

6).Strengthening structure of soil

7).Protection engineering of seaside area.

Applications:

1.Control and guide of water or flood

2.Flood bank or guiding bank

3.Preventing of rock breaking

4.Water and soil protection

5.Bridge protection

6.Strengthening structure of soil

7.Protection engineering of seaside area

Installation

Step 1: Flat packed Gabion

Gabions are delivered on site in folded condition (flat-packed) on a pallet. All vertical joints are factory fitted which increases the quality and speed of assembly on site. Depending upon the configuration of the Gabion, the base and lid panels are connected with 1 horizontal and helical. The accessories (bracing ties and joining pins) are prefabricated and adjusted to the Gabion type. To close the base and lids additional spirals are necessary.

Gabions are delivered on site in folded condition (flat-packed) on a pallet. All vertical joints are factory fitted which increases the quality and speed of assembly on site. Depending upon the configuration of the Gabion, the base and lid panels are connected with 1 horizontal and helical. The accessories (bracing ties and joining pins) are prefabricated and adjusted to the Gabion type. To close the base and lids additional spirals are necessary.

Step 2: Pull until full length

Take a Gabion from a pallet and cut the securing brace. Lift the accessories and pull the Gabion until full length is reached. Close the base helically and fold the ends 90. Now the spirals won't detach when moving and turning the Gabion. This will also prevent sharp end and injuries. This can be done with standard pliers. Now turn over the Gabion.

Take a Gabion from a pallet and cut the securing brace. Lift the accessories and pull the Gabion until full length is reached. Close the base helically and fold the ends 90. Now the spirals won't detach when moving and turning the Gabion. This will also prevent sharp end and injuries. This can be done with standard pliers. Now turn over the Gabion.

Step 3: Joining

For large lengths, the Gabions should be connected as to form a monolithic structure. Prefabricated joining pins are provided for each Gabion. Simply grasp the 2 spirals then push them into each other. Place the joining pin into the section and push it downwardly. Care must be taken that the head of the pin faces should be inward. This must be done for security reasons and will prevent vandalism. The joining must be done at both sides.

For large lengths, the Gabions should be connected as to form a monolithic structure. Prefabricated joining pins are provided for each Gabion. Simply grasp the 2 spirals then push them into each other. Place the joining pin into the section and push it downwardly. Care must be taken that the head of the pin faces should be inward. This must be done for security reasons and will prevent vandalism. The joining must be done at both sides.

Step 4: Bracing ties

As to prevent heavy deformation caused by filling the Gabions, bracing ties are included in each Gabion. Depending upon the height of the gabion, these are placed at 1/3 + 2/3 or 1/2 of the height.

Now start filling the first part of the Gabion.

Bracing ties are placed 4 meshes from the sides and around the weld. If not, the weld can break or the bracing tie can move. Repeat this principle until the Gabions are fully filled.

Step 5: Closing the lid

After filling the Gabion, the lid can be closed. Use the included spirals and attach the lid at every edge including the diaphragm panel. Also twist the ends inwardly for safety reasons.

When super positioning Gabions, the horizontal connections must be done. This is usually carried out with the help of clips or lacing wire.

As to prevent heavy deformation caused by filling the Gabions, bracing ties are included in each Gabion. Depending upon the height of the gabion, these are placed at 1/3 + 2/3 or 1/2 of the height.

Now start filling the first part of the Gabion.

Bracing ties are placed 4 meshes from the sides and around the weld. If not, the weld can break or the bracing tie can move. Repeat this principle until the Gabions are fully filled.

Step 5: Closing the lid

After filling the Gabion, the lid can be closed. Use the included spirals and attach the lid at every edge including the diaphragm panel. Also twist the ends inwardly for safety reasons.

When super positioning Gabions, the horizontal connections must be done. This is usually carried out with the help of clips or lacing wire.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Welded Wire Mesh Gabion

Welded Mesh Gabion Box

Welded Mesh Gabion Baskets

Gabion Wire Mesh

Gabion Baskets Mesh

Hexagonal Gabion Wire Mesh

More>>