|

HeBei TuoHua Metal Products Co., Ltd.

|

Hot-dipped Welded Gabion Box

| Price: | 10.0~50.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

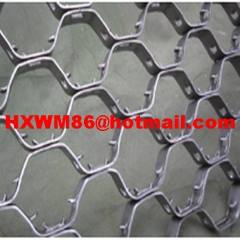

Welded Gabion Box is constructed of rugged hight tensile wire which is coated with a thick, cor-rosion-resistant layer of zinc.

Welded Gabion Box

Easy to install

Field installation is quick and easy. In fact, installation time can be as much as 40% less than required by hex type gabions. With diaphragms and stiffeners installed,the gabion may be filled with standard loading equipment.After filling the gabion, a lid is placed on top and secured with spiral binders,lacing wire or "C" rings.

Unlike hexagonal units, our hongxin welded wire Gabion hold their shape better – they don't bulge out when filled .They are easy to handle,which means more work,less labor and highter productivity an the job.

Material:

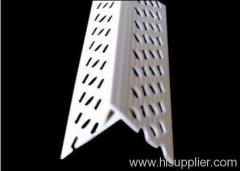

Welded gabions box are made of welded wire fabrics, compared with those woven gabions, gabions made of welded wire fabrics are with more strength, which will not bulge when under pressure. This kinds of material is easy, fast to erect and do not need tensioning. With such features welded gabion box is easy to keep its shape without bulges.

Welded gabion box is usually filled with stone to form steady structure for retaining of the riverbank and soils

Specification:

Standard welded gabion material: Galvanized, PVC coated

Standard welded gabion wire diameter: 3.0-6.0mm

Standard welded gabion opening: 76*76mm, 50*50mm, 100*100mm, 50*200mm

Standard welded gabion spring wire diameter: 3.0mm-5.0mm

Material:

Welded gabions box are made of welded wire fabrics, compared with those woven gabions, gabions made of welded wire fabrics are with more strength, which will not bulge when under pressure. This kinds of material is easy, fast to erect and do not need tensioning. With such features welded gabion box is easy to keep its shape without bulges.

Welded gabion box is usually filled with stone to form steady structure for retaining of the riverbank and soils

Coating Properyt | Test Method | Value |

Tensile Strength | ASTM D638 | 2275Min |

Elongation | ASTM D638 | 290% No Break |

Hardness | ASTMD2240 | 75Min Shore A |

Salt Sproy | ASTM B 117 | 3000hrs.no effect |

Exposure to Ultraviolet Light | ASTM 1499 ASTMG23 | 3000hrs |

Specification:

Standard welded gabion material: Galvanized, PVC coated

Standard welded gabion wire diameter: 3.0-6.0mm

Standard welded gabion opening: 76*76mm, 50*50mm, 100*100mm, 50*200mm

Standard welded gabion spring wire diameter: 3.0mm-5.0mm

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Welded Gabion Box

Galvanized Welded Gabion Box

Welded Mesh Gabion Box

Welded Wire Gabion Box

Welded Gabion

Hot Dipped Galvanized Wire

More>>