|

HeBei TuoHua Metal Products Co., Ltd.

|

cheap Polyester Forming Fabric

| Price: | 10.0~80.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

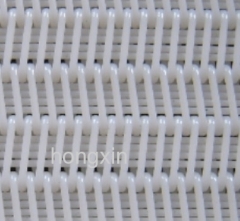

This kind of Polyester forming fabric is standard type of polyester forming fabric in paper making, mainly used for producing cultural paper,

Polyester forming fabric

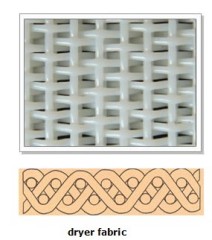

According to the weaving, polyester forming fabric can be divided into 4-shed, 5-shed, 7-shed, 8-shed, 16-shed, 24-shed etc. According to the category, it can be divided into single layer fabric, double layer fabric, two-and a half layer fabric and three-layer fabric

*4-shed single layer Polyester forming fabric is standard type of polyester forming fabric in paper making, mainly used for producing cultural paper, printing paper, packing paper and so on.

*5-shed single layer Polyester forming fabric is suitable for making healthy paper, culture paper and packing paper etc.

*8-shed single layer Polyester forming fabric is the most wear-resisting one in the single layer screen, which have long performance life, but mesh print is relatively deep. It is mainly used for copying the papermaking bag, craft paper, cardboard, corrugated paper and so on.

*7-shed double layer Polyester forming fabric is suitable for quality printing paper and tissue paper etc.

*8-shed double layer Polyester forming fabric is suitable for quality printing paper, tissue paper and the surface pulp and inner pulp of the board paper etc.

*8-shed, 16-shed double and a half layer Polyester forming fabric is suitable for making quality printing paper, tissue paper and surface pulp, inner pulp and base pulp of the board paper etc.

*Multi-shed three-layer Polyester forming fabric is suitable for making quality printing paper, tissue paper and cigarette paper etc.

*4-shed single layer Polyester forming fabric is standard type of polyester forming fabric in paper making, mainly used for producing cultural paper, printing paper, packing paper and so on.

*5-shed single layer Polyester forming fabric is suitable for making healthy paper, culture paper and packing paper etc.

*8-shed single layer Polyester forming fabric is the most wear-resisting one in the single layer screen, which have long performance life, but mesh print is relatively deep. It is mainly used for copying the papermaking bag, craft paper, cardboard, corrugated paper and so on.

*7-shed double layer Polyester forming fabric is suitable for quality printing paper and tissue paper etc.

*8-shed double layer Polyester forming fabric is suitable for quality printing paper, tissue paper and the surface pulp and inner pulp of the board paper etc.

*8-shed, 16-shed double and a half layer Polyester forming fabric is suitable for making quality printing paper, tissue paper and surface pulp, inner pulp and base pulp of the board paper etc.

*Multi-shed three-layer Polyester forming fabric is suitable for making quality printing paper, tissue paper and cigarette paper etc.

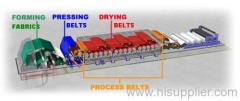

Application

- for paper substance dewatering and thickening

- for wooden boards substance dewatering and thickening

- clothes for dewatering drums and thickening drums

- for wooden boards substance dewatering and thickening

- clothes for dewatering drums and thickening drums

Advantages :

1.Improved paper machine efficiencies

2.Enhanced sheet smoothness

3.Increased fiber support

4.Excellent stability

5.Low drag load

6.Low water carry

7.High fiber support

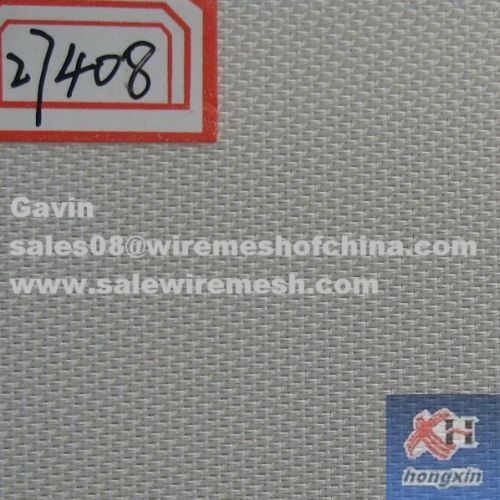

Specification of this kind of polyester forming fabric:

Category: Single layer fabric

Model: CXW27408

Warp wire diameter: 0.20mm

Weft wire diameter: 0.40mm

Warp wire density: 31 pieces/cm

Weft wire density: 17.5 pieces/cm

Mesh surface strength: ≥700N/cnm

Interface strength: ≥450N/cnm

Thickness: 0.9mm

Air permeation: 420CFM

The elongation : ≤0.60% (under tension of 50N/cm)

Model: CXW27408

Warp wire diameter: 0.20mm

Weft wire diameter: 0.40mm

Warp wire density: 31 pieces/cm

Weft wire density: 17.5 pieces/cm

Mesh surface strength: ≥700N/cnm

Interface strength: ≥450N/cnm

Thickness: 0.9mm

Air permeation: 420CFM

The elongation : ≤0.60% (under tension of 50N/cm)

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Polyester Forming Fabric Mesh

Polyester Fabric

Cheap Usb

Dazzle Polyester Fabric

Nonwoven Polyester Fabric

Coated Polyester Fabric

More>>